BMD BWTS ASAP

#ballastwatertreatment #marineindustry #boksaboatsandbarges #compliance www.bmdinc.com

Engineering for Ballast Water Treatment Systems

Boksa Marine Design (BMD) provides engineering solutions to install and commission ballast water treatment systems (BWTS) with full regulatory approval.

Space constraints and demands on electrical and piping systems makes installing BWTS on existing vessels more complicated than new builds.

USCG requires BWTS installation on all vessels with their first scheduled drydocking since 2016.

BMD navigates the nuances of your BWTS new build or refit. Contact us for compliant solutions that are engineered for the sea at info@bmdinc.com.

Boksa Marine Design Engineered for the Sea. From Home.

As Boksa Marine Design’s team practices social distancing for compliance and safety, we continue engineering robust, stout vessels from our individual home offices to support your shipyard and client requirements, meeting all deliverables on schedule and on budget. We are performing remote surveys; our staff recently completed a a FaceTime inspection of a fire system to avoid travel and to help lake vessels back to work after the winter.

The world needs ships, barges, push tugs and commercial marine vessels for defense, exploration, commerce and transportation of critical supplies.

As Boksa Marine Design’s team practices social distancing for compliance and safety, we continue engineering robust, stout vessels from our individual home offices to support your shipyard and client requirements, meeting all deliverables on schedule and on budget. We are performing remote surveys; our staff recently completed a a FaceTime inspection of a fire system to avoid travel and to help lake vessels back to work after the winter.

BMD remains anchored in faith with our marine industry colleagues until this crisis is successfully managed for the public health. Feel free to reach out by phone, e-mail, FaceTime or Skype for questions and updates. While everyone is dry-docked at home, anticipate BMD engaging the air waves with exciting, new digital campaigns on multiple platforms for your convenience and interest.

Let us know how you are doing during the quarantine. Be safe and be well!

Thank you,

Nick Boksa PE

Leave the Nest. Production engineering, 3D modeling, lofting and nesting of structure.

Boksa Marine Design combines manufacturing technology with management science, using the most advanced marine engineering practices to solve management challenges related to production. Our goal is to accomplish the production process in the smoothest, most judicious and economic way for our clients.

Lofting and Nesting of Metal Parts

3D Modeling and Space Planning

Production Drawings

Boksa Marine Design combines manufacturing technology with management science, using the most advanced marine engineering practices to solve management challenges related to production. Our goal is to accomplish the production process in the smoothest, most judicious and economic way for our clients.

We provide efficient solutions for every stage of the project lifecycle, from establishing the vessel mission to design development and engineering to overseeing the final build. Boksa Marine Design can manage the entire marine design process for you - or assist with specific design services.

PRODUCTION ENGINEERING

Lofting and Nesting of Metal Parts

FRP Tooling Design

Production Drawings

3D Modeling

3D Pipe Routing and Spooling

3D Space Planning

Modular Design

Engineered for the Sea. Hardworking, durable vessels built to last.

Since 2003, BMD has completed 565 projects up to 740-feet for over 50 clients, including the world’s leading shipyards. Founded by naval architect and marine engineer, Nicholas Boksa, P.E., the majority of the firm’s marine engineers have actually worked on ships at sea. Proven skills and resources incorporating years of knowledge with cutting edge technology make every Boksa design robust, stout and crew friendly, truly engineered for the sea.

Since 2003, BMD has completed 565 projects up to 740-feet for over 50 clients, including the world’s leading shipyards. Founded by naval architect and marine engineer, Nicholas Boksa, P.E., the majority of the firm’s marine engineers have actually worked on ships at sea. Proven skills and resources incorporating years of knowledge with cutting edge technology make every Boksa design robust, stout and crew friendly, truly engineered for the sea.

Form follows function and Boksa boats are designed, engineered and built to exceed the operational requirements of their unique mission, meeting class standards and regulatory and flag state requirements.

In additional to complete naval architecture, conceptual designs and styling, BMD also provides production engineering, systems engineering, structural / electrical / mechanical engineering, hull design, outfitting design, stability analysis, project support, classification society compliance, and complete refit engineering for the commercial marine industry, including research vessels, workboats, ferries, and inland river and shallow draft markets, as well as the luxury superyacht industry. BMD’s team comprises 11 marine professionals, including seven engineers with a wide array of expertise and practical experience building in steel, aluminum and composite.

About Nicholas Boksa, KP ‘95

Nick Boksa graduated from the United States Merchant Marine Academy (USSMA) with a B.S. in Marine Engineering Systems. At USMMA, Boksa earned a USCG 3rd assistant engineer merchant mariner license. He attained the rank of Lt. Commander in the U.S. Merchant Marine Reserves and obtained his masters degree in naval architecture and marine engineering from the University of Michigan.

Before launching his own firm, Nick Boksa worked at Burger Boat Company as a naval architect, responsible for hull design, structural engineering, weights and centers, powering and performance, mechanical systems and outfitting for Burger hulls 483 - 493, all semidisplacement motoryachts ranging from 76 - 118 feet. Boksa then joined Maritrans, Inc. as a naval architect and marine engineer responsible for design and construction management of a fleet of oceangoing tugboats and large oil tank barges (ATBs). As naval architecture and engineering manager for Davis Boatworks, Boksa designed semi-custom FRP sport fishing yachts up to 70 feet, with the fleet’s speed exceeding 45 knots. Significant experience with iconic, industry leaders in diverse markets is a bonus for BMD’s clients expecting proven engineering and naval architecture solutions.

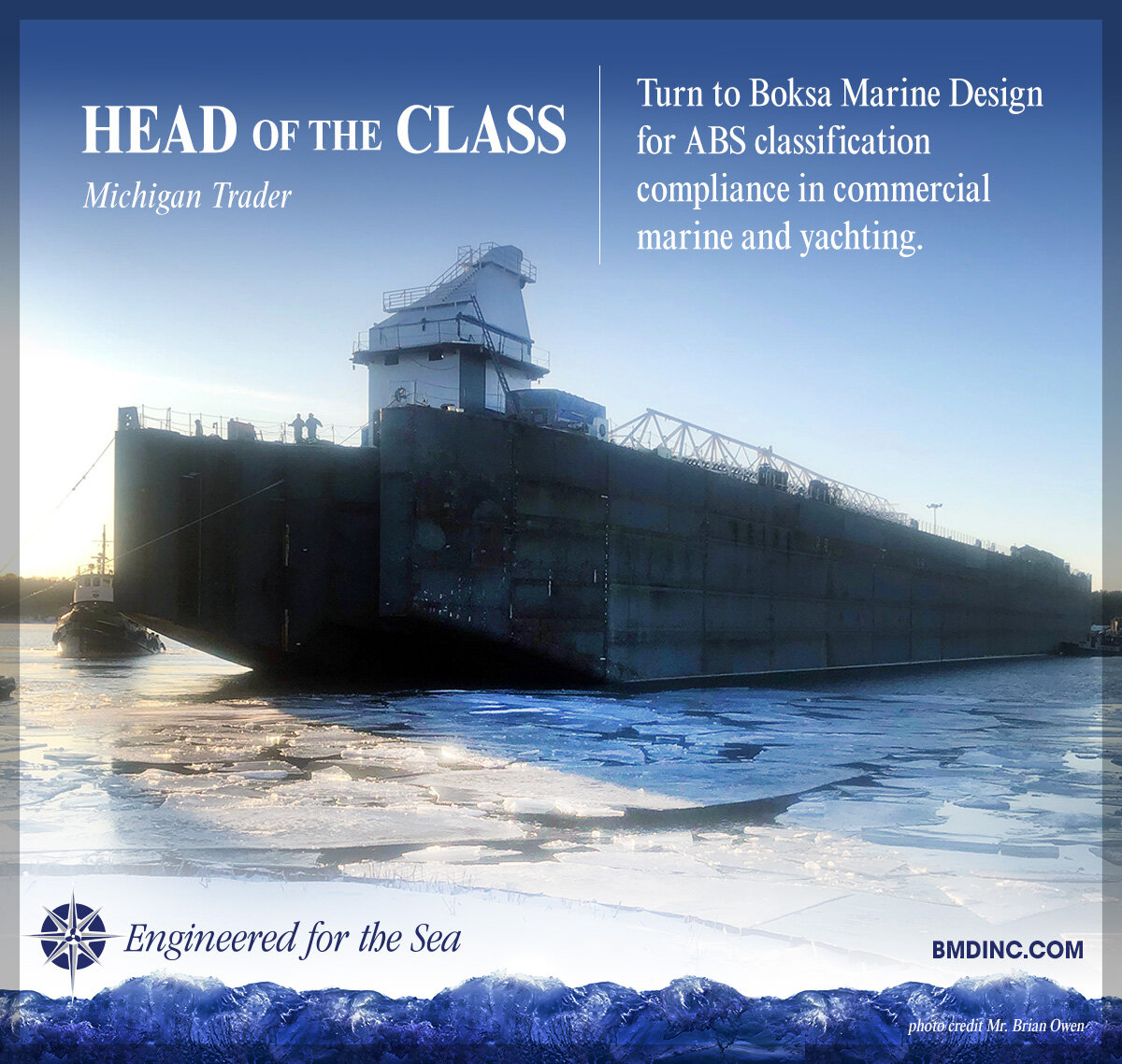

Head of the Class

Barge MICHIGAN TRADER is the third sister in a series of self-unloading barges for the Great Lakes, currently under construction at Fincantieri Bay Shipbuilding in Sturgeon Bay, WI for Van Enkevort Tug & Barge. Boksa Marine Design has provided construction support throughout the build, updating the design and bringing her up to date to current class and USCG requirements.

Set to deliver in July 2020, the 740’x78’ MICHIGAN TRADER was floated out of the graving dock to make room for the Great Lakes winter fleet which arrived for winter refit work. In the spring, she will be redocked and finished.

No matter the type of vessel or the location of new build construction/refit, BMD’s marine engineers and naval architects will navigate the complete life cycle of your project. Boksa Marine Design is up to date on the latest regulatory requirements and best practices of the marine industry to achieve ABS class certification and compliance.

Boksa Boats & Barges

Progress photos of Boksa’s barge production progress photo at Donjon Shipyard. bmdinc.com #barges #boksaboats #donjon